Pressure swing adsorption (PSA) oxygen generators provide a constant supply of pure oxygen from ambient air. They are used in many medical and industrial applications that require an on-site oxygen source. But how does PSA technology actually work to separate oxygen from nitrogen?

Overview of PSA Oxygen Generation

PSA generators utilize a molecular sieve made of zeolite to adsorb nitrogen from compressed air. This leaves an oxygen-enriched product stream that can reach over 90% purity.

The PSA process operates in a cyclic fashion. Air is pressurized and fed into vessels containing the zeolite adsorbent. The zeolite selectively traps nitrogen molecules while allowing oxygen to pass through. After the adsorbent becomes saturated, the pressure is reduced to desorb and release the nitrogen. This regeneration step reactivates the zeolite so it can repeat the adsorption process in the next cycle.

How Zeolite Molecular Sieves Work

The zeolite used in PSA generators contains tiny pores that trap nitrogen while allowing oxygen to flow freely. This molecular sieve material has a higher affinity for nitrogen compared to oxygen.

Some properties that make zeolite effective for PSA oxygen generation include:

- High surface area within its porous structure

- Ability to adsorb nitrogen rapidly under pressure

- Easy desorption of nitrogen when pressure reduced

- High selectivity for nitrogen over oxygen

Zeolite adsorbents like this allow PSA systems to produce oxygen with over 90% purity.

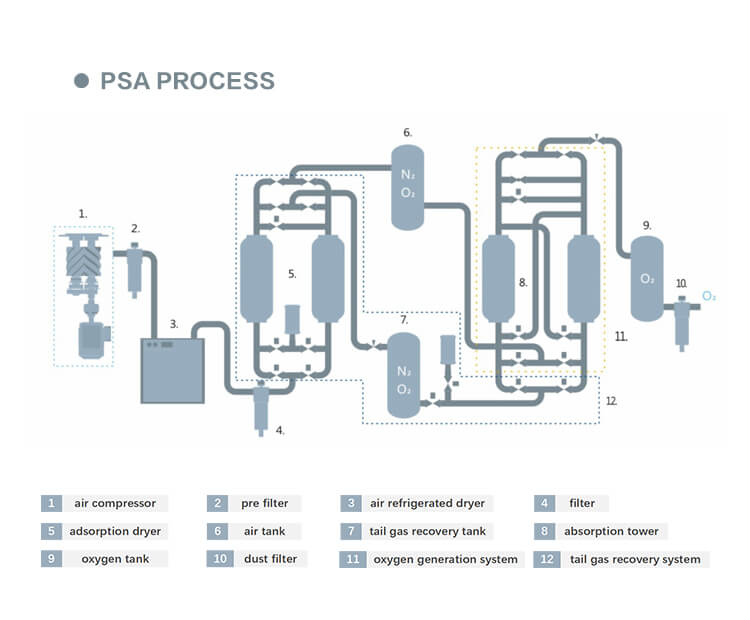

PSA Process Steps Explained

The PSA oxygen generation process involves cycling between higher-pressure adsorption and lower-pressure desorption. Here are the key steps:

- Pressurization – The air compressor feeds ambient air into one vessel. This starts the adsorption phase.

- Nitrogen Adsorption – At the higher pressure, nitrogen molecules within the air are preferentially adsorbed onto the zeolite.

- Oxygen Production – Purified oxygen passes through the adsorbent bed and exits the vessel. This product gas is over 90% oxygen.

- Desorption – Before nitrogen saturates the zeolite, the vessel is depressurized. This allows the trapped nitrogen to be desorbed.

- Purge – Some product oxygen flows back through the vessel to purge out the released nitrogen gas. This regenerates the adsorbent.

- Depressurization – The vessel returns to higher pressure and repeats the adsorption phase.

While one vessel is in adsorption mode, the other vessel undergoes desorption/purge to continually produce oxygen gas.

Major Components of a PSA Generator

A PSA oxygen generation system contains the following main components:

- Air compressor – Compresses inlet air to required pressures

- Air tanks – Stores the compressed air and buffers flow

- Molecular sieve beds – Contain zeolite to adsorb nitrogen

- Oxygen storage – Stores purified oxygen product

- Control panel – Automates PSA cycle through valves

- Tubing & valves – Direct air flows for adsorption and desorption

The PSA cycle is controlled by automated pneumatic valves that open and close to direct air to the proper vessel. This provides a smooth, continuous supply of oxygen.

Getting Your Own PSA Oxygen Generator

If you need an on-site oxygen supply, Oxynitra offers customized PSA oxygen generators for medical, industrial, and lab uses. With 40+ years of expertise in PSA technology, Oxynitra can deliver reliable, high-purity oxygen generation systems to meet your specific requirements.

Conclusion

PSA oxygen generators produce a continuous oxygen supply by adsorbing nitrogen onto zeolite molecular sieves. The principles of pressure swing adsorption, specialized zeolite adsorbents, and system automation allow PSA generators to supply high-purity oxygen for various on-site needs.