Nitrogen Generator

Reliable industrial nitrogen gas generation system - customized for your application

This gas generator enables reliable production of nitrogen gas on-site to reduce costs and enhance supply chain efficiency. With flow rates up to 5,000 Nm3/hr and purity levels reaching 99.9999%, it is ideal for industrial nitrogen supply.

- Nitrogen flow: 10~5,000Nm3/hr

- Nitrogen purity: 90~99.9999%

- Nitrogen pressure: 0.5Mpa~1.2Mpa

- Nitrogen dew point:-70 °C~-45 °C

Find The Right Nitrogen Generator for You

Skid-Mounted Nitrogen Generator

The skid-mounted nitrogen generators offer a compact, self-contained nitrogen production package mounted on a heavy-duty skid frame.

- Fully assembled unit with compressor, adsorbent towers, controls, and piping shipped ready to install.

- Skid allows the system to be easily moved and positioned with a forklift.

- Simplifies installation with single-point connections for power, inlet feed air, and outlet nitrogen.

- Small, modular footprint minimizes required space. Units can be installed indoors or outdoors.

- Ideal solution for nitrogen supply in manufacturing facilities, chemical plants, refineries, and gas distributors.

Containerized Nitrogen Generator

The containerized all-in-one package provides reliable, ready-to-use on-site nitrogen precisely where you need it.

- Fully self-contained, skid-mounted system with compressor, PSA towers, and controls housed in a 20 ft or 40 ft insulated container.

- Turnkey “generator in a box” enables quick installation and commissioning on-site with minimal site work needed.

- Rugged construction stands up to harsh environments for offshore, desert, mining and other remote locations.

- Low noise and compact footprint suitable for urban sites with strict noise regulations.

Standardized PSA Nitrogen Generator

OxyNitra provides a reliable standardized nitrogen generation solution for various industrial applications with up to 5,000 Nm3/hr flow rate.

- Cost-effective PSA nitrogen generator based on proven, robust design.

- Turnkey package with air compressor, air treatment, PSA towers, and buffer tank integrated.

- Touchscreen HMI for monitoring of key parameters and automatic unattended operation.

- Optional nitrogen booster available.

Stainless Steel Nitrogen Generator

For applications requiring exceptional corrosion resistance and sanitary construction, we offer stainless steel nitrogen generators.

- All wetted surfaces made of 316L stainless steel.

- Ideal for supplying nitrogen to food, beverage, pharmaceutical, and chemical industries where stainless construction is essential.

- Electropolished interior and exterior provides smoother surfaces for easy cleaning, sterility, and inhibition of bacterial growth.

- Available in skid-mounted or containerized.

Horizontal Nitrogen Generator

Our horizontal nitrogen generators are engineered for installations with height or overhead clearance restrictions, especially underground environments.

- All major components are integrated horizontally on a skid frame with a low profile.

- Ideal for underground facilities, mines, tunnels, and other subterranean working areas with height limits.

- Compact footprint and small size allows transport underground via winding gear or conveyance.

- Touchscreen panel angled upwards for easy monitoring and access.

All-in-one Nitrogen Generator

This all-in-one nitrogen generators integrate every component into a single skid-mounted unit for maximum simplicity.

- Fully self-contained system with filtration, PSA towers, buffer tank, and power distribution.

- Reduces installation time and cost by eliminating complex site connections.

- Single-point connections for inlet air, nitrogen outlet, electricity.

- Touchscreen HMI provides control, monitoring, and diagnostics in one central interface.

- Complete pre-engineered package allows rapid deployment to any location.

How Our Nitrogen Generators Improve Your Operations

Reduce Your Nitrogen Supply Costs By Up to 60%

By generating nitrogen on-site with a PSA nitrogen generator, you can eliminate the costs of delivered liquid nitrogen or high-pressure cylinder supplies and benefit from payback periods as short as 1~2 years.

Just-in-Time Continuous Supply

Say goodbye to fluctuating supply from nitrogen tank deliveries. Our PSA units provide a continuous, stable flow of nitrogen whenever you need it.

Improved Operational Safety

Reduce handling risks associated with high-pressure nitrogen cylinders and liquid cryogenic supply tanks with our safe on-site generation solution.

Minimal Maintenance Requirements

With no moving parts and durable adsorbent materials, we’ve engineered these generators for years of reliable low-maintenance operation between routine servicing.

The Many Uses of On-Site Nitrogen Supply

PSA Nitrogen Generator Working Principle

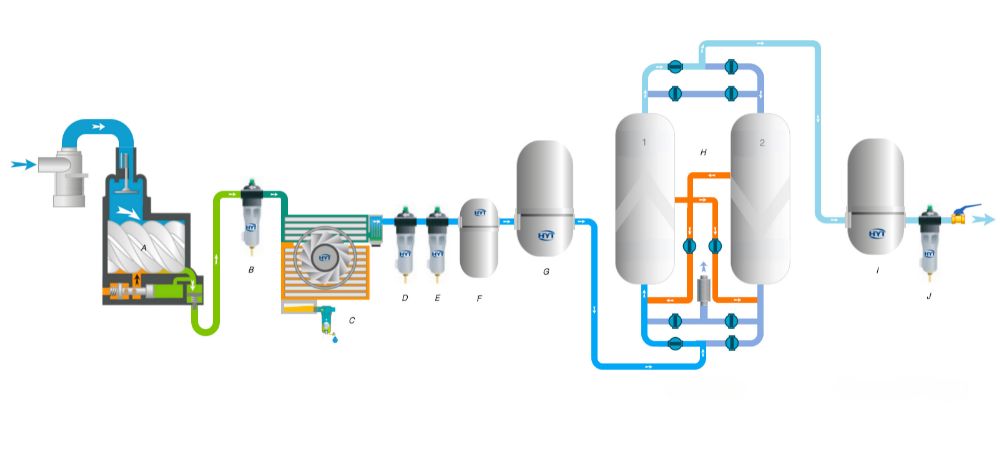

PSA nitrogen generators utilize pressure swing adsorption technology to extract nitrogen gas from compressed air, providing an on-site nitrogen supply.

OxyNitra PSA nitrogen generators use two adsorption towers filled with Carbon Molecular Sieve (CMS) material. This CMS contains many microscopic pores that have different adsorption capacities for nitrogen and oxygen molecules under pressure.

The towers alternately cycle through adsorption and desorption:

- Adsorption – One tower uses pressure to adsorb oxygen onto the CMS, allowing high-purity nitrogen to flow through continuously.

- Desorption – The other tower releases the trapped oxygen in a desorption process, regenerating the CMS for the next production cycle.

This synchronized switching between the two CMS-filled PSA towers provides a reliable, non-stop supply of on-site nitrogen. The proprietary CMS and precision tower cycling are key to generating nitrogen for industrial applications.

Frequently Asked Questions

Yes, we can provide fully customized engineering and design to suit your needs. Contact us to discuss requirements.

Standard models ship within 4-6 weeks after purchase order. For custom systems please contact us for estimated lead times. Expedited shipping available.

With proper maintenance, our nitrogen generators typically have a lifespan of 15-20 years in industrial use.

We have spare parts kits available for all common wearing components, filters, and consumables. This simplifies maintenance and reduces downtime.

We have an experienced in-house team available for commissioning, troubleshooting, and technical support worldwide. Support is available online, via phone, email, and onsite.

Our standard models are designed for simple installation without any foundations needed.

Ready for a more reliable, cost-effective nitrogen supply?

Contact us today to discuss the advantages of on-site nitrogen generation system and how we can help meet your specific requirements.