Oxygen Generator

Custom-Engineered Onsite Oxygen Supply

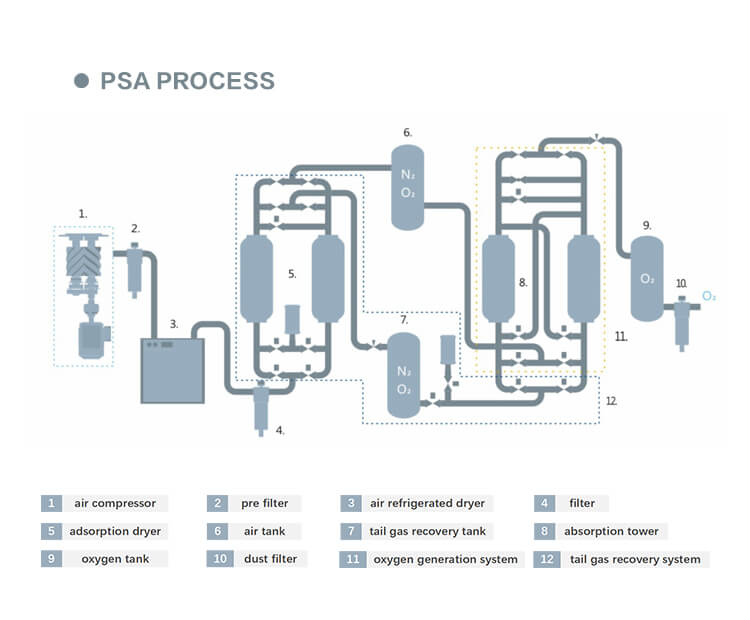

OxyNitra oxygen generation systems utilize an advanced pressure swing adsorption (PSA) process to produce oxygen gas on-site for industrial facilities.

By extracting oxygen directly from ambient air, our systems eliminate the need for bulk liquid oxygen deliveries or high pressure cylinder supplies.

- Oxygen flow: 1~3,000Nm3/hr

- Oxygen purity: 80~99.5%

- Oxygen pressure: 0.5Mpa~1.0Mpa

- Oxygen dew point:-70 °C~-45 °C

Find The Right Oxygen Generator for You

Skid-Mounted Oxygen Generator

OxyNitra skid-mounted oxygen generation systems offer a self-contained, ready-to-install solution with all components factory pre-assembled on a compact skid.

- Components like compressor, air treatment, PSA towers, and buffer tank integrated and piped on a skid frame.

- Small footprint minimizes required floor space.

- Single-point connections for feed air, oxygen outlet, and power hookup.

- Touchscreen HMI provides control, monitoring, and diagnostics.

- Optional oxygen compression and storage packages available.

- Ideal for industrial gas suppliers, chemical plants, metal fabrication, fish farms and more.

Containerized Oxygen Generator

For fast and easy deployment, OxyNitra containerized oxygen generation systems provide a complete solution in a standard shipping container.

- Fully self-contained, skid-mounted system installed inside a 20 ft or 40 ft insulated container.

- Turnkey “generator-in-a-box” enables quick installation on-site with minimal site work.

- Rugged construction for offshore, mining, and other remote/harsh location operation.

- Compact and quiet system ideal for urban locations with noise restrictions.

- Optional air treatment and oxygen compression packages available.

The all-in-one containerized oxygen generator package provides reliable, ready-to-use oxygen supply precisely where needed. Contact us to discuss sizing a containerized oxygen generation system tailored to your project requirements!

Standardized PSA Oxygen Generator

The standardized oxygen generation system package based on proven, robust PSA technology ideal for industrial applications.

- Cost-effective pre-engineered oxygen generator for simplified purchasing.

- Touchscreen HMI enables automated unattended operation.

- Oxygen purity of 90% +/- 3% at capacities up to 600 Nm3/hr.

- Outlet pressure adjustable from 3 to 10 barg.

- Optional oxygen compression and storage available.

High Purity 99.5% Oxygen Generator

For critical processes that demand contaminant-free oxygen, this ultra high purity oxygen system generates oxygen on-site with 99.5% purity.

- Multi-stage PSA technology with enhanced purification produces 99.5% pure oxygen.

- Ideal for industries like electronics, photonics, optical fiber manufacturing.

- Removes hydrocarbon, CO, CO2, and moisture impurities to <0.5 ppm levels.

- Comprehensive monitoring with oxygen purity analyzer.

Trust OxyNitra to deliver contaminant-free ultra high purity oxygen for your most demanding applications requiring up to 99.5% oxygen.

Medical Oxygen Generator

OxyNitra medical oxygen generator generates on-site oxygen for healthcare facilities and hospitals per medical grade oxygen standards.

- Oxygen purity of 93% +/- 3% exceeds requirements of medical oxygen USP and EP.

- Specially designed molecular sieve materials to avoid trace contaminants.

- Polishing filters remove oil vapors, VOCs, CO, and CO2 to trace levels.

- Touchscreen display shows oxygen concentration, operating pressures.

- Alarm and shutdown functions for out-of-spec oxygen or faults.

- Flow rates from 1 – 200 Nm3/hr at adjustable pressures.

- Optional oxygen storage tank and backup cylinders.

OxyNitra provides hospitals an independent on-site medical oxygen supply, giving peace of mind even during emergencies or shortages.

All-in-one Oxygen Generator

This all-in-one oxygen generators integrate every component into a single skid-mounted package for maximum convenience.

- Fully self-contained plug-and-play system with air compressor, filtration, PSA towers, buffer tank, and power distribution.

- Minimal installation time and costs by eliminating complex site connections.

- Single-point connections for inlet air, oxygen outlet, and electricity.

- Touchscreen HMI enables control, monitoring, and diagnostics in one interface.

- Complete pre-engineered package for fast deployment anywhere needed.

With minimal foundation work required, our all-in-one oxygen generators enable turnkey supply even in remote locations. Perfect for temporary surge capacity or quickly establishing new oxygen supply.

Reasons to Switch to Onsite Oxygen Supply

Reduce Oxygen Supply Costs by up to 60%

On-site oxygen generation using PSA technology can cut your oxygen gas costs by 60% compared to delivered liquid oxygen or cylinder supplies.

Just-in-Time Continuous Oxygen Supply

Say goodbye to fluctuating oxygen inventory. Our oxygen generation systems provide a stable, continuous oxygen supply on demand.

Improved Operational Safety

On-site oxygen generation enhances safety by avoiding risks associated with handling high-pressure oxygen cylinders and cryogenic liquid oxygen.

Minimize Process Interruptions

With no deliveries needed, your own oxygen generators help avoid production disruptions from supply logistics issues.

Oxygen Supply Solutions for Your Market

PSA Oxygen Generator Working Principle

OxyNitra PSA oxygen generators use two adsorption towers filled with Zeolite Molecular Sieve (ZMS) material. The ZMS contains many microscopic pores that have different adsorption capacities for nitrogen and oxygen molecules under pressure.

The two towers work in synchronized cycles:

- Pressurized Adsorption – One tower uses pressure to adsorb nitrogen onto the ZMS, allowing high-purity oxygen to flow through continuously.

- Desorption – The other tower releases the trapped nitrogen in a desorption process, regenerating the ZMS for the next production cycle.

- Switching – The towers repeatedly switch between adsorption and desorption modes to maintain constant oxygen generation.

This reliable pressure swing adsorption production process generates a steady supply of on-site oxygen to meet industrial demands, without the need for delivered liquid oxygen or cylinders.

Frequently Asked Questions

We have extensive expertise across chemical production, metals manufacturing, food and beverage, aquaculture, water treatment, hospital and more.

Lead times range from 4-12 weeks depending on the oxygen capacity. Please inquire for current lead time estimates.

With proper maintenance, our oxygen generators typically have a lifespan of 15-20 years in industrial use.

Yes, we stock spare parts kits with common expendables like filters. We can also pre-bundle tailored spare parts packages with your initial purchase.

Yes, we offer on-site operator training during commissioning and can provide refresher training courses for maintenance personnel if desired.

Yes, our oxygen generators are suitable for outdoor installation. Certain enclosure upgrades may be recommended depending on the operating climate.

Ready for a more reliable, cost-effective oxygen supply?

Contact us today to discuss the advantages of on-site oxygen generation system and how we can help meet your specific requirements.